The fan is designed for reducing volume of gas in mining sections and eliminating methane accumulations at the junctions of rooms and air gates in coal mines

VTsG-7M FAN

APPLICATION OFVTsG-7M FAN

VTsG-7M fan is designed for reducing volume of gas in mining sections and eliminating methane accumulations at the junctions of rooms and air gates in coal mines dangerous due to gas and dust, by sucking methane-air mixtures from the mined-out space and removing them through rigid pipelines.

The fan is installed in a special chamber or working and is connected to a suction or discharge pipeline.

The fan is installed in a special chamber or working and is connected to a suction or discharge pipeline.

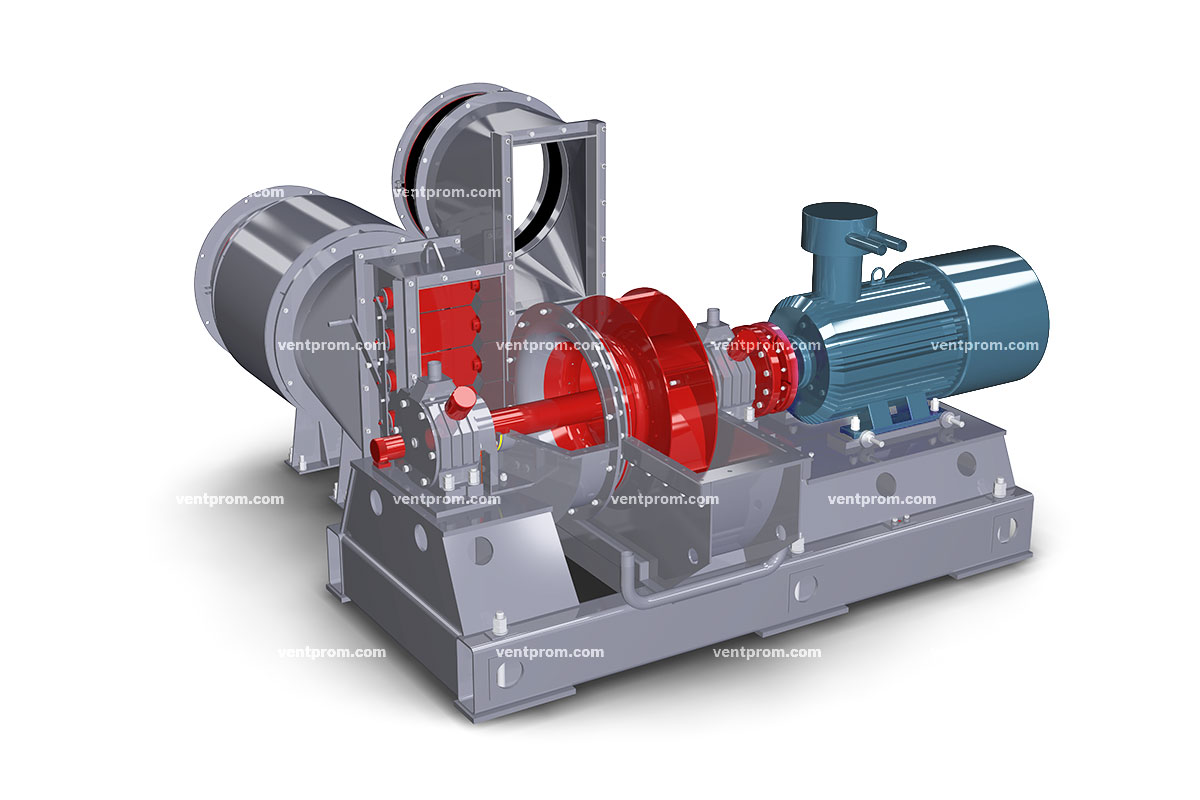

Electric motor

Rotor

Frame

Split housing

Bearing housing

VTsG-7M design and features

Fans consist of a split housing, a rotor installed in two bearings, a frame, a guide vane, a motor, a noise muffler, an inlet and outlet pipes.

Pressure and flow rate are adjusted by the guide vane.

Pressure and flow rate are adjusted by the guide vane.

—

modern aerodynamic design with a high-pressure characteristic

—

thermal and vibration protection with the function of switching off the fan when heating and exceeding the bearings vibration normal value

—

explosion-proof electric motor

—

brass seals in places of possible frictional sparking

—

impeller blades are filled with foam, preventing protecting from the water ingress

—

dynamic balancing of the impeller according to a high accuracy class of

—

highly reliable design of the guide vane, allowing smoothly changing the power and direction of the air jet

—

thick lubrication of bearing units

—

especially rigid massive metal structures of the frame and housing

—

original petal coupling between motor and rotor

—

noise muffler with extended service life

modern aerodynamic design with a high-pressure characteristic

—

thermal and vibration protection with the function of switching off the fan when heating and exceeding the bearings vibration normal value

—

explosion-proof electric motor

—

brass seals in places of possible frictional sparking

—

impeller blades are filled with foam, preventing protecting from the water ingress

—

dynamic balancing of the impeller according to a high accuracy class of

—

highly reliable design of the guide vane, allowing smoothly changing the power and direction of the air jet

—

thick lubrication of bearing units

—

especially rigid massive metal structures of the frame and housing

—

original petal coupling between motor and rotor

—

noise muffler with extended service life

AERODYNAMIC CHARACTERISTICS

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS