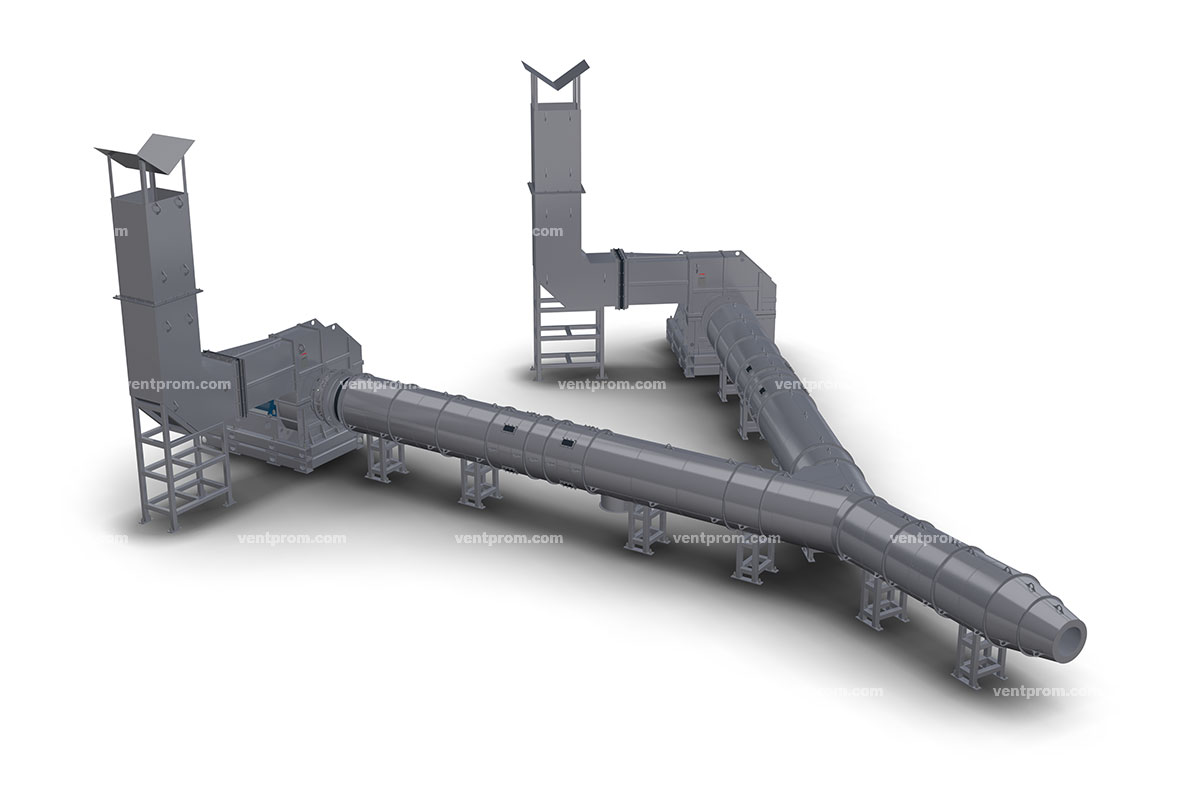

UVTsG-9M2 gas-suction plant with fans for use on the mine surface is designed to remove methane-air mixtures with methane concentration from 0 to 100% from the mine sections through ventilation shafts and wells

UVTsG-9M2 gas drainage plant

APPLICATION OF UVTsG-9М2gas-drainage plant

UVTsG-9M2 gas-suction plant with fans for use on the mine surface is designed to remove methane-air mixtures with methane concentration from 0 to 100% from the mine sections through ventilation shafts and wells

Exhaust pipe

Volute chamber

UVTsG-9M Fans

Moisture separator

Flame arrester

Centrifugal separator

Flow switch

Flexible inserts

Aerodynamic valve

Connecting pipes

Design and features

Plant composition:

— UVTsG-9M Fans

— Flow switches

— Aerodynamic valve

— Flexible inserts

— Connecting pipes

— Volute chamber

— Exhaust pipes

— Flame arrester

— Moisture separator

— Connecting and transition pipes

— UVTsG-9M Fans

— Flow switches

— Aerodynamic valve

— Flexible inserts

— Connecting pipes

— Volute chamber

— Exhaust pipes

— Flame arrester

— Moisture separator

— Connecting and transition pipes

Measuring pipe has the ability to install standard sensors for measuring the gas level, temperature of the transported air, speed or pressure, or measure with portable sensors. There is also a window for freshening up the gas stream

Flame arrester consists of a housing, flame arresting elements and safety valves.

Loss of pressure in the flame arrester with nominal pipe size of 1000 mm are:

in the nominal mode (14 m³/s) – 180 Pa;

in the maximum mode (24 m³/s) – 525 Pa,

which is maximum 5% of the pressure developed by the fan

Centrifugal separator is designed to separate moisture and dust from the air stream.

Consists of a swirler, a drip collector and a volute chamber. The flow switch consists of two aerodynamic cut-off valves of "aerodynamic duct door" type located on the suction lines of each fan, a common aerodynamic, and a joining T-pipe.

The flow switch consists of two aerodynamic cut-off valves of "aerodynamic duct door" type located on the suction lines of each fan, a common aerodynamic, and a joining tee.

—

To prevent freezing of air duct elements, all elements, pipes, tees, valves, moisture separators, fire arrestors and adapters to the well have frame design, with internal cavities filled with heat-insulating material.

Flame arrester consists of a housing, flame arresting elements and safety valves.

Loss of pressure in the flame arrester with nominal pipe size of 1000 mm are:

in the nominal mode (14 m³/s) – 180 Pa;

in the maximum mode (24 m³/s) – 525 Pa,

which is maximum 5% of the pressure developed by the fan

Centrifugal separator is designed to separate moisture and dust from the air stream.

Consists of a swirler, a drip collector and a volute chamber. The flow switch consists of two aerodynamic cut-off valves of "aerodynamic duct door" type located on the suction lines of each fan, a common aerodynamic, and a joining T-pipe.

The flow switch consists of two aerodynamic cut-off valves of "aerodynamic duct door" type located on the suction lines of each fan, a common aerodynamic, and a joining tee.

—

To prevent freezing of air duct elements, all elements, pipes, tees, valves, moisture separators, fire arrestors and adapters to the well have frame design, with internal cavities filled with heat-insulating material.

Noise reduction measures

At the request of the customer fan exhaust elements can be made with noise suppression elements.

All these elements are made of a perforated sheet, noise-absorbing material is laid and sheathed with sheet material.

All these elements are made of a perforated sheet, noise-absorbing material is laid and sheathed with sheet material.

—

Application of a fan volute chamber and an exhaust pipe allows reducing the noise characteristics by 30 dBA and will amount to 85 dBA.

—

For greater noise reduction, a noise-absorbing pipe has been developed. Application of such pipe allow reducing the noise by another 7 dBA. Pipe installation between the volute chamber and the exhaust pipe. To achieve the required noise reduction level, install several pipes

Application of a fan volute chamber and an exhaust pipe allows reducing the noise characteristics by 30 dBA and will amount to 85 dBA.

—

For greater noise reduction, a noise-absorbing pipe has been developed. Application of such pipe allow reducing the noise by another 7 dBA. Pipe installation between the volute chamber and the exhaust pipe. To achieve the required noise reduction level, install several pipes

TECHNICAL SPECIFICATIONS

AERODYNAMIC CHARACTERISTICS

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS