The VOM-18 axial-flow fan is designed to provide forced air supply in tunnels and underground stations. The fan can be used to ventilate road tunnels and other engineering structures.

VОМ-18 FAN

VOM-18 fan application

The VOM-18 axial-flow fan is designed to provide forced air supply in tunnels and underground stations. The fan can be used to ventilate road tunnels and other engineering structures. The airflow is reversed by the simultaneous rotation of the straightener blades by 180° and (changing the motor rotor rotation direction)

—

The fan can be equipped with an automatic control system

—

The fan can be equipped with an automatic control system

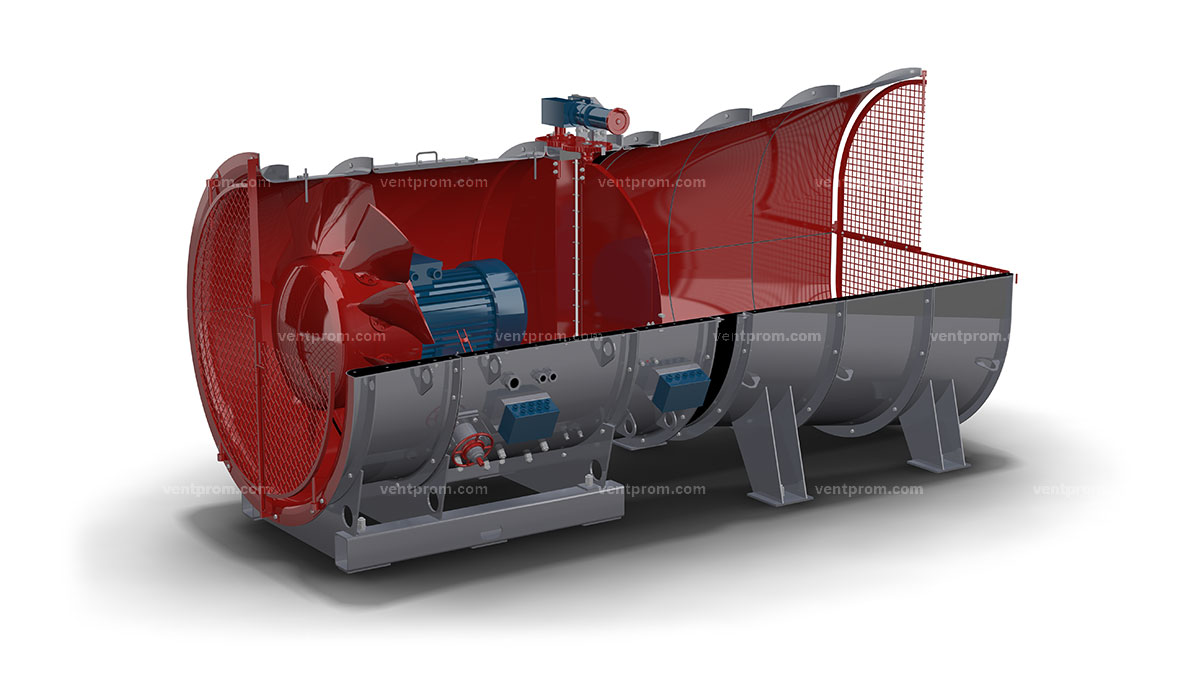

Drive motor

Damper

Fan housing

Manifold with enclosure

Frame

Retaining mechanism

Working wheel

Volute chamber

Design and features

Fan VOM-18 consists of a housing, a straightener, a rotor, an impeller blades turning mechanism drive, a straightener blades turning mechanism (CA), drive motor on a stand, a coupling, a volute chamber, a chimney valve with a drive, a hand brake and a common base frame bolted to a fixed base, and an air flow and pressure measuring station.

—

For preventive inspections of the impeller blades, the housing is equipped with hatches on both sides and a horizontal split.

—

The rotor with the impeller mounted on the shaft on a tapered fit, rotates in two spherical roller bearings.

—

The impeller blades rotate from 150° to 450° in direct operation and 180° in reverse operation.

—

The impeller blades are rotated by an electric drive.

—

The straightener consists of a housing, rotating blades, and a chain mechanism.

—

Simultaneous rotation of the apparatus blades is performed from the actuator through one of the blades and the chain gear.

—

The blades are rotated by the actuator into three positions: direct operation, reversing operation, and middle position (chimney valve).

—

To prevent air leakage through a non-operating fan, there is a chimney valve consisting of two flaps that automatically gate the flow section through a system of levers when the fan is stopped.

—

The fan is equipped with an air flow and pressure measurement station, which includes a forward-flow dynamic pressure receiver, a reverse-flow dynamic pressure receiver, and two static-flow receivers.

—

To prevent the rotor from turning during repairs and inspections, the fan is equipped with a manual brake with a limit switch to prevent the drive motor from starting when the fan is braked.

—

If it is necessary to reverse the air stream, the drive motor is stopped (by electrodynamic braking), after which the CA blades and impeller blades are rotated to the position corresponding to the reverse operation, and the drive motor is started with a change in direction of rotation.

For preventive inspections of the impeller blades, the housing is equipped with hatches on both sides and a horizontal split.

—

The rotor with the impeller mounted on the shaft on a tapered fit, rotates in two spherical roller bearings.

—

The impeller blades rotate from 150° to 450° in direct operation and 180° in reverse operation.

—

The impeller blades are rotated by an electric drive.

—

The straightener consists of a housing, rotating blades, and a chain mechanism.

—

Simultaneous rotation of the apparatus blades is performed from the actuator through one of the blades and the chain gear.

—

The blades are rotated by the actuator into three positions: direct operation, reversing operation, and middle position (chimney valve).

—

To prevent air leakage through a non-operating fan, there is a chimney valve consisting of two flaps that automatically gate the flow section through a system of levers when the fan is stopped.

—

The fan is equipped with an air flow and pressure measurement station, which includes a forward-flow dynamic pressure receiver, a reverse-flow dynamic pressure receiver, and two static-flow receivers.

—

To prevent the rotor from turning during repairs and inspections, the fan is equipped with a manual brake with a limit switch to prevent the drive motor from starting when the fan is braked.

—

If it is necessary to reverse the air stream, the drive motor is stopped (by electrodynamic braking), after which the CA blades and impeller blades are rotated to the position corresponding to the reverse operation, and the drive motor is started with a change in direction of rotation.

Operation

For different operating conditions, chamber depths, climatic zones, the fan is available in four designs:

1 with rotating impeller blades on the run and volute chamber;

2 with rotating impeller blades on the run;

3 without rotating impeller blades on the run and a volute chamber;

4 without rotating the impeller on the move.

1 with rotating impeller blades on the run and volute chamber;

2 with rotating impeller blades on the run;

3 without rotating impeller blades on the run and a volute chamber;

4 without rotating the impeller on the move.

The housing of VOM series fans for easy transportation, installation, and service can be manufactured of metal structures with vertical and / or horizontal connectors. There are inspection and installation hatches located on the housing. The fan blades and hub are made of aluminum alloy. The original design of the blade attachment keeps the blade from turning spontaneously.

The fan can be equipped with a device for supply and pressure monitoring, consisting of pressure receivers and a set of control and measuring equipment, as well as a device for monitoring the temperature and vibration of the motor bearings

—

To be installed on-site in the ventilating chamber.

—

To be used in single-fan / dual-fan installations.

—

Used for ventilation in emergency mode at a temperature of 400 C for 2 hours.

—

Designed for operation at ambient air temperatures from -45 oC to +50 oC and relative humidity up to 98%.

—

Intended for ventilation of tunnels and underground stations

The fan can be equipped with a device for supply and pressure monitoring, consisting of pressure receivers and a set of control and measuring equipment, as well as a device for monitoring the temperature and vibration of the motor bearings

—

To be installed on-site in the ventilating chamber.

—

To be used in single-fan / dual-fan installations.

—

Used for ventilation in emergency mode at a temperature of 400 C for 2 hours.

—

Designed for operation at ambient air temperatures from -45 oC to +50 oC and relative humidity up to 98%.

—

Intended for ventilation of tunnels and underground stations

TECHNICAL SPECIFICATIONS

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS