VОМ-16М FAN

The VOM-16М fan is designed to provide main ventilation of underground stations and operate as components of ventilation systems of enterprises in other industries, used for the movement of air and compatible gases.

VOM-16V fan application

The VOM fans are designed to provide main ventilation of tunnels and underground stations and operate as components of ventilation systems of enterprises in other industries, used for the movement of air and compatible gases.

—

The fans can be equipped with automatic control systems

—

The fans can be equipped with automatic control systems

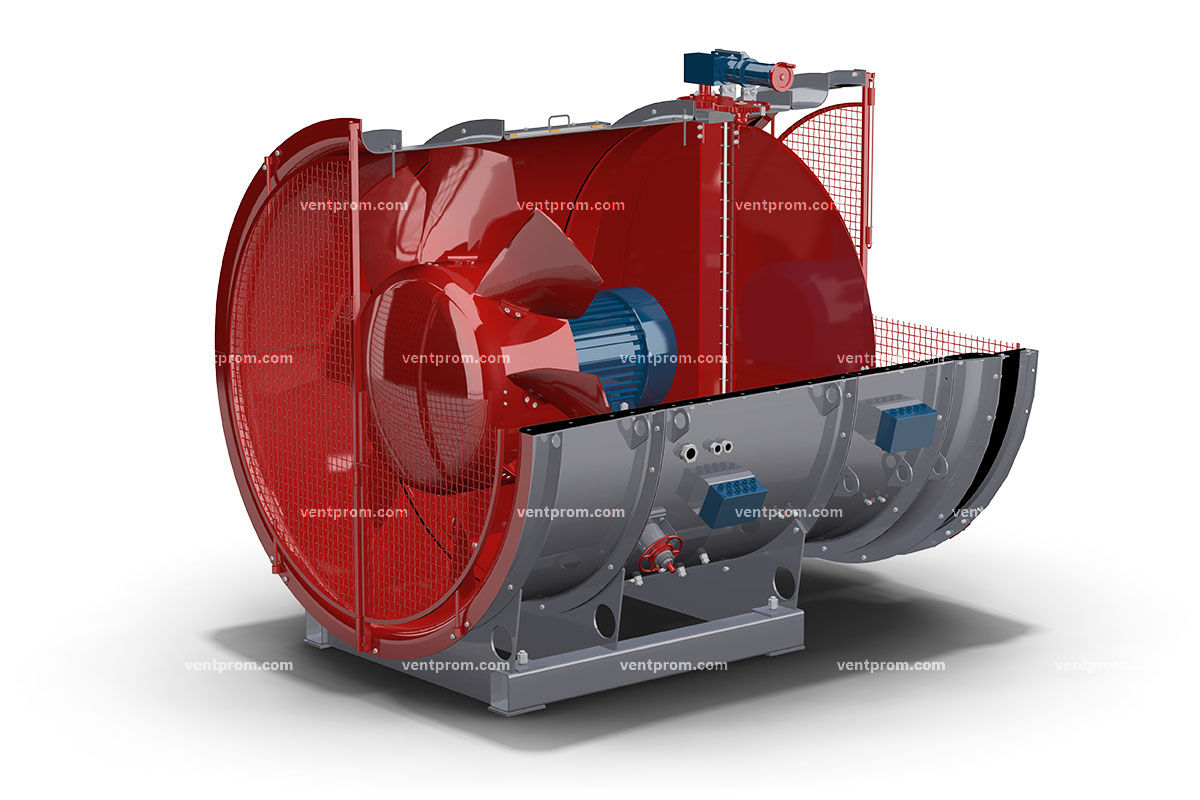

Damper

Fan housing

Manifold with enclosure

Drive motor

Retaining mechanism

Frame

VOM-16M.00.000 version with two manifolds. Straightener blades are rotated by a drive.

VOM-16M.00.000-01 version with a manifold and a damper. Straightener blades are stationary.

VOM-16M.00.000-02 version with a manifold and a damper. Straightener blades are manually rotated.

VOM-16M.00.000-03 version with two manifolds. On common frame.Straightener blades are rotated by a drive.

VOM-16M.00.000-04 version with a manifold and a damper. Straightener blades are manually rotated. On common frame.

VOM-16M fan design and features

The VOM-16M fan consists of a steel welded housing, rotor, straightener with 14 rotating blades and a rotation mechanism, spinners and manifolds, an electric motor with a rack. The rotor consists of a shaft with an impeller.

—

The shaft rotates in two spherical roller bearings.

—

The bearings are greased by remote grease nipples

—

The impeller blades are fixed on a steel bushing by spring rings, so that they can be turned by any angle within 15–45 ˚C when the fan is stopped.

—

The fan is reversible.

—

The airflow is reversed by changing the rotation direction of the electric drive motor while simultaneously altering the setting angle of the straightener blades.

—

The reversing provides more than 60% of the air supply in comparison with the direct operation.

—

The electric drive performs the simultaneous rotation of the straightener blades through the chain gear.

—

To adjust the fan parameters, turn its working blades within 15–45 degrees through the housing maintenance hole.

The shaft rotates in two spherical roller bearings.

—

The bearings are greased by remote grease nipples

—

The impeller blades are fixed on a steel bushing by spring rings, so that they can be turned by any angle within 15–45 ˚C when the fan is stopped.

—

The fan is reversible.

—

The airflow is reversed by changing the rotation direction of the electric drive motor while simultaneously altering the setting angle of the straightener blades.

—

The reversing provides more than 60% of the air supply in comparison with the direct operation.

—

The electric drive performs the simultaneous rotation of the straightener blades through the chain gear.

—

To adjust the fan parameters, turn its working blades within 15–45 degrees through the housing maintenance hole.

TECHNICAL SPECIFICATIONS

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS