The VOD-30 axial two-stage fan is designed for main ventilation systems of coal and ore mines.

VOD-30 FAN

VОМ-30 fan application

The VOD series axial fans (VOD-16P, VOD-18, VOD-21M, VOD-30, VOD-40, VOD-50) are designed for main ventilation of coal and ore mines, as well as ventilation systems of plants in other industries, used to move air and non-aggressive gases.

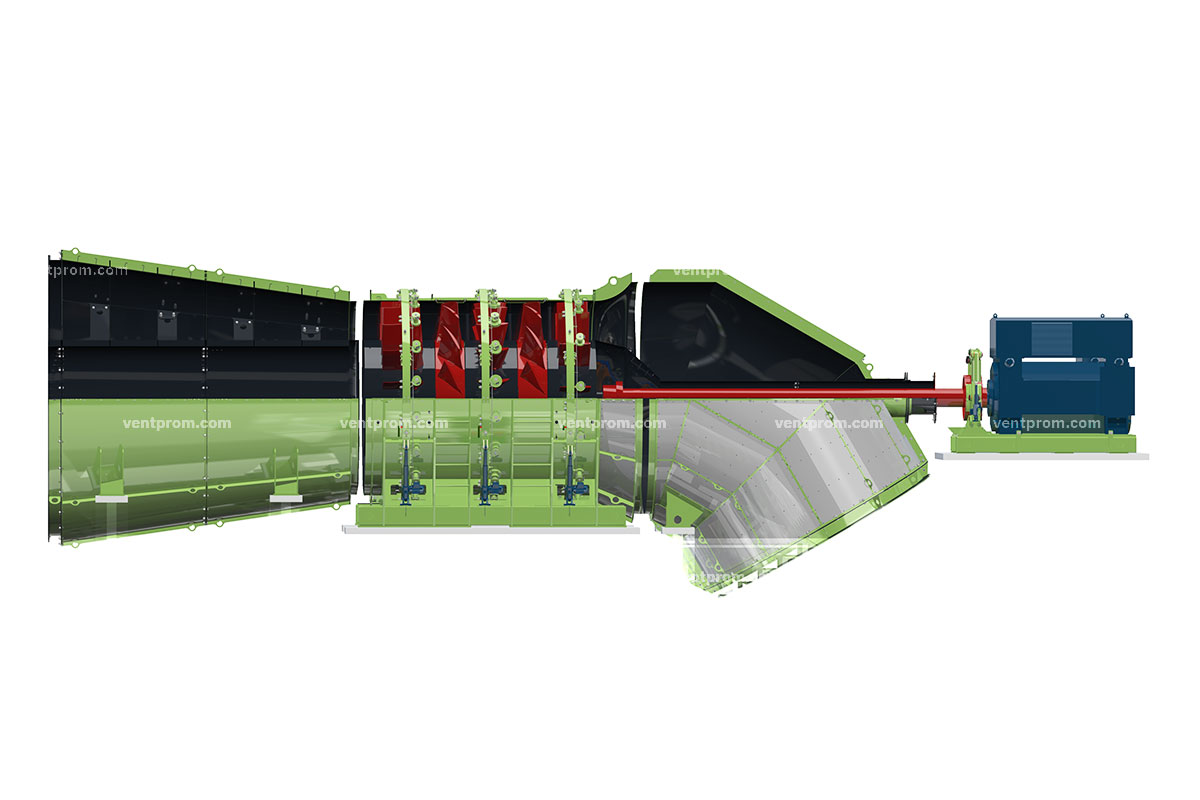

The VOD-30 axial two-stage fan has the following configuration: К1 + НА + К2 + СА, where:

К1 — impeller of the 1st stage

К2 — impeller of the 2nd stage

GV — guide vane

S — straightener.

The VOD-30 axial two-stage fan has the following configuration: К1 + НА + К2 + СА, where:

К1 — impeller of the 1st stage

К2 — impeller of the 2nd stage

GV — guide vane

S — straightener.

Electric drive motor

Housing with a horizontal connector

Guide vane and straightener

Transmission shaft

VOD-30 fan design

The fan consists of the following main assemblies and parts: an electric motor, a brake, a transmission shaft, a spinner, a manifold, a front support block, a rotor, a housing with a guide vane, a rear support block with a straightener, a diffuser, two beams, a lubrication system, an airflow and pressure measurement station.

The airflow is reversed by changing the rotation direction of the electric drive motor while simultaneously changing the setting angle of the both guide vane and straightener blades. Reversing provides 60-70% of the air supply for direct operation without the use of bypass ducts.

The fans can be used for both suction and discharge ventilation systems.

The airflow is reversed by changing the rotation direction of the electric drive motor while simultaneously changing the setting angle of the both guide vane and straightener blades. Reversing provides 60-70% of the air supply for direct operation without the use of bypass ducts.

The fans can be used for both suction and discharge ventilation systems.

—

The spinner, collector, front support block, housing with guide vane, rear support block with straightener, diffuser and beams are welded structures.

—

The VOD-30 fan rotor consists of two impellers mounted on a shaft, radial and angular contact bearings. The rotor rotates in rolling bearings.

—

The fan impeller is a hub with twelve rotating blades mounted around its circumference.

—

The blade is held on the wheel by a split conical bushing. When set to the required performance angle, it is fixed in the rim with two clamps.

—

The blades are rotated to the required angle and replaced through hatches in the housing.

—

The fan is connected to the drive motor by means of an unsupported suspension type transmission shaft with two toothed unidirectional clutches.

—

The fan is equipped with a pad brake, which is actuated by an electromagnetic drive.

—

The both guide vane and straightener blades are welded, and of special shape. Simultaneous rotation of the blades is done by an electric drive through the drive ring, flexible links and drums.

—

Lubrication of the fan bearings is done by oil circulation from oil station. Bearing lubrication of fans with impeller diameter up to 2.1 m is of grease type, and with larger diameters is of circulating type.

—

In order to prevent oil leakage through the bearing seal into the fan cavity, the lubrication system and the oil pan are hermetically sealed. This equalizes the pressure in the lubrication system and in the bearings, and ensures normal operation without leakage.

—

The temperature of the bearings is monitored by temperature sensors. It is possible to install two temperature sensors in radial bearings, and four sensors in angular contact bearings.

—

The fan can be supplied with a set of reversing and flow switching devices. The kit for reversing the air stream and switching from an operating fan to a standby one consists of two switch doors for switching in the suction channel, a diffuser door, and three winches.

—

The fan is equipped with a device for measuring the flow and pressure. It consists of a pressure receiver and a set of control and measuring equipment.

The spinner, collector, front support block, housing with guide vane, rear support block with straightener, diffuser and beams are welded structures.

—

The VOD-30 fan rotor consists of two impellers mounted on a shaft, radial and angular contact bearings. The rotor rotates in rolling bearings.

—

The fan impeller is a hub with twelve rotating blades mounted around its circumference.

—

The blade is held on the wheel by a split conical bushing. When set to the required performance angle, it is fixed in the rim with two clamps.

—

The blades are rotated to the required angle and replaced through hatches in the housing.

—

The fan is connected to the drive motor by means of an unsupported suspension type transmission shaft with two toothed unidirectional clutches.

—

The fan is equipped with a pad brake, which is actuated by an electromagnetic drive.

—

The both guide vane and straightener blades are welded, and of special shape. Simultaneous rotation of the blades is done by an electric drive through the drive ring, flexible links and drums.

—

Lubrication of the fan bearings is done by oil circulation from oil station. Bearing lubrication of fans with impeller diameter up to 2.1 m is of grease type, and with larger diameters is of circulating type.

—

In order to prevent oil leakage through the bearing seal into the fan cavity, the lubrication system and the oil pan are hermetically sealed. This equalizes the pressure in the lubrication system and in the bearings, and ensures normal operation without leakage.

—

The temperature of the bearings is monitored by temperature sensors. It is possible to install two temperature sensors in radial bearings, and four sensors in angular contact bearings.

—

The fan can be supplied with a set of reversing and flow switching devices. The kit for reversing the air stream and switching from an operating fan to a standby one consists of two switch doors for switching in the suction channel, a diffuser door, and three winches.

—

The fan is equipped with a device for measuring the flow and pressure. It consists of a pressure receiver and a set of control and measuring equipment.

TECHNICAL SPECIFICATIONS

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS