The VOKD-3.6 axial two-stage fan is designed for the main ventilation systems of large mines in the coal, mining, potash and other mining industries.

VOKD-3,6 FAN

VОKD-3.6 fan application

The VOKD-3.6 axial two-stage fan is designed for the main ventilation systems of large mines in the coal, mining, potash and other mining industries. The fans can also be used in industrial ventilation systems for handling air and non-corrosive gases.

The fan provides wide performance and pressure regulation by changing the blade angles of the impellers (when the fan is stopped) and the flaps of the intermediate guide vane (when the fan is running).

The VOKD-3.6 fan is designed to operate at 375 and 500 rpm. The recommended operational rpm is 375.

The fan provides wide performance and pressure regulation by changing the blade angles of the impellers (when the fan is stopped) and the flaps of the intermediate guide vane (when the fan is running).

The VOKD-3.6 fan is designed to operate at 375 and 500 rpm. The recommended operational rpm is 375.

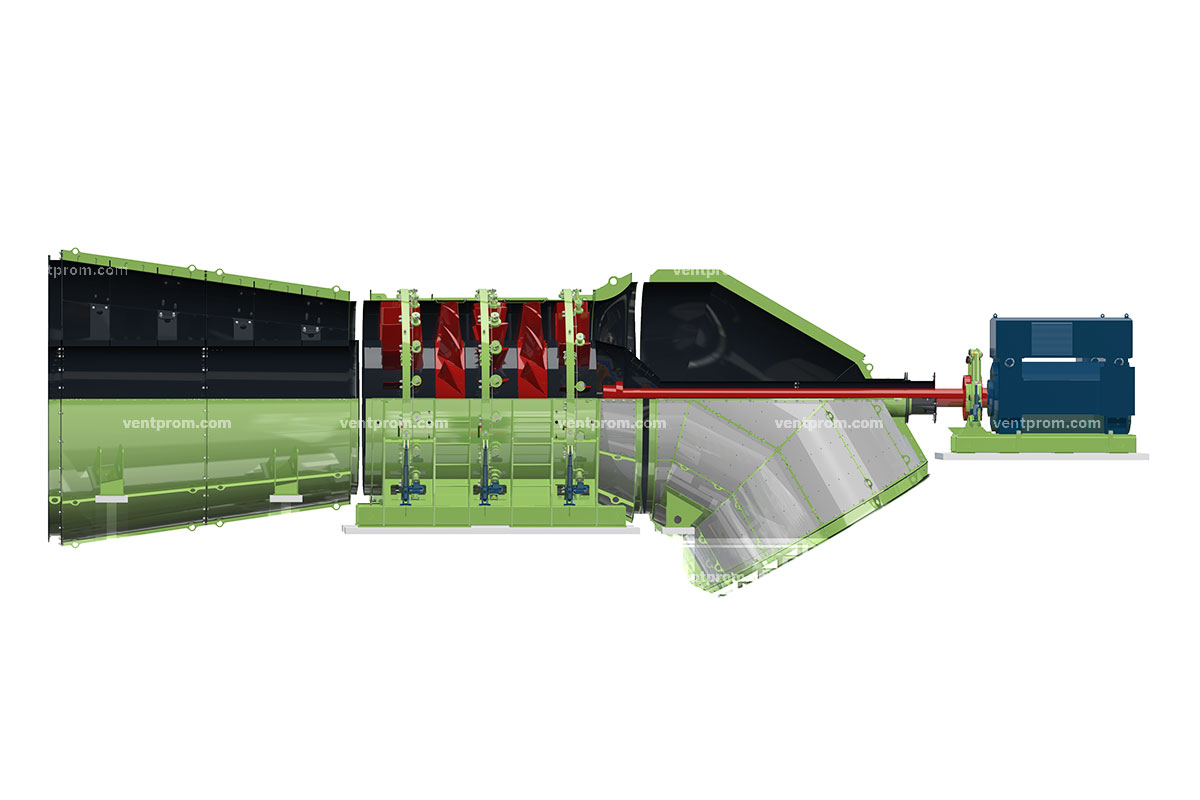

Electric drive motor

Steel blades with reinforcing rib

Impeller hubs

Transmission shaft

Design and special features

The VOKD-3.6 fan consists of a rotor, front and rear support blocks, a casing, a transmission shaft, a brake, a spinner, a manifold, a diffuser, a frame, an electric drive motor and a lubrication system.

The rotor consists of a shaft, radial and angular contact bearings, and impellers.

The fan casing is sectional, consisting of two support blocks (front and rear) and a welded casing located between them. In the middle part of the housing there is a guide vane with swivel blade flaps. The flap turning mechanism is remotely controlled by a servo.

The diffuser, manifold, spinner and fan frame are welded, made of sheet and sectional steel.

Mine ventilation system consists of two VOKD-3.6 fans, auxiliary equipment (six air duct doors and winch), electric drive motors, automation equipment and building structures.

Key features of new ventilation systems are compact size, simple design, high operational reliability, and ease of maintenance and repair.

Careful aerodynamics optimization of the system's flow channel and its individual active aerodynamic elements ensures a minimum level of static pressure loss;

The rotor consists of a shaft, radial and angular contact bearings, and impellers.

The fan casing is sectional, consisting of two support blocks (front and rear) and a welded casing located between them. In the middle part of the housing there is a guide vane with swivel blade flaps. The flap turning mechanism is remotely controlled by a servo.

The diffuser, manifold, spinner and fan frame are welded, made of sheet and sectional steel.

Mine ventilation system consists of two VOKD-3.6 fans, auxiliary equipment (six air duct doors and winch), electric drive motors, automation equipment and building structures.

Key features of new ventilation systems are compact size, simple design, high operational reliability, and ease of maintenance and repair.

Careful aerodynamics optimization of the system's flow channel and its individual active aerodynamic elements ensures a minimum level of static pressure loss;

—

The fan is connected to the drive motor by a suspended type transmission shaft with two toothed unilateral couplings.

—

Steel blades have a reinforcing rib that protects the blade front edge from wear and tear by dust and moisture in the mine air.

—

The design of the swivel elbow-flaps of the flow switch group together with a special flow alignment vane system is optimized by finite element analysis and balanced relative to the pivotal axis, which ensures minimum effort and quick rearrangement ;

—

The rotor radial loads are carried by paired single row cylindrical roller bearings mounted in spherical cages. The axial load is transmitted through an integral angular contact bearing. Bearing grease is liquid and of circulating type. It is supplied by fan oil station. Bearing temperature is monitored with resistance thermometers.

—

Impeller hubs are welded-cast and sealed, which eliminates the possible rotor imbalance due to dust ingress. Twelve twisted profiled blades are attached to the hubs by means of a threadless quick-turn cone bolt.

—

Efficient flow switch sealing system reduces air leaks during operation;

—

The pad break provides fast stopping and locking of the fan rotor.

—

Elements of each fan unit are mounted on a common frame, which provides increased reliability of the 'motor-fan' system;

—

Closed duct system (atmospheric duct communicates is connected to the outlet diffuser) guarantees non-frosting of the ventilation system at sub-zero temperatures;

—

The vertical design of the diffuser and the special lining of its inner surface provide effective noise suppression and its good radiation pattern.

The fan is connected to the drive motor by a suspended type transmission shaft with two toothed unilateral couplings.

—

Steel blades have a reinforcing rib that protects the blade front edge from wear and tear by dust and moisture in the mine air.

—

The design of the swivel elbow-flaps of the flow switch group together with a special flow alignment vane system is optimized by finite element analysis and balanced relative to the pivotal axis, which ensures minimum effort and quick rearrangement ;

—

The rotor radial loads are carried by paired single row cylindrical roller bearings mounted in spherical cages. The axial load is transmitted through an integral angular contact bearing. Bearing grease is liquid and of circulating type. It is supplied by fan oil station. Bearing temperature is monitored with resistance thermometers.

—

Impeller hubs are welded-cast and sealed, which eliminates the possible rotor imbalance due to dust ingress. Twelve twisted profiled blades are attached to the hubs by means of a threadless quick-turn cone bolt.

—

Efficient flow switch sealing system reduces air leaks during operation;

—

The pad break provides fast stopping and locking of the fan rotor.

—

Elements of each fan unit are mounted on a common frame, which provides increased reliability of the 'motor-fan' system;

—

Closed duct system (atmospheric duct communicates is connected to the outlet diffuser) guarantees non-frosting of the ventilation system at sub-zero temperatures;

—

The vertical design of the diffuser and the special lining of its inner surface provide effective noise suppression and its good radiation pattern.

TECHNICAL SPECIFICATIONS

AERODYNAMIC CHARACTERISTICS

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS