Electric air heater is designed to heat the air supplied by the main fan systems in the mines. Heaters must work in conjunction with the automatic control system for air heating devices.

ELECTRIC

AIR HEATERS

ELECTRIC AIR HEATERS PURPOSE

Electric air heater is designed to heat the air supplied by the main fan systems in the mines. Heaters must operate in conjunction with the automatic control system for air heating devices (SAU-UNV)

The system cabinets degree of protection against electric shock, as well as the degree of protection of the product from penetration of solid foreign bodies is IP54 according to GOST 14254-80.

The system cabinets degree of protection against electric shock, as well as the degree of protection of the product from penetration of solid foreign bodies is IP54 according to GOST 14254-80.

Housing

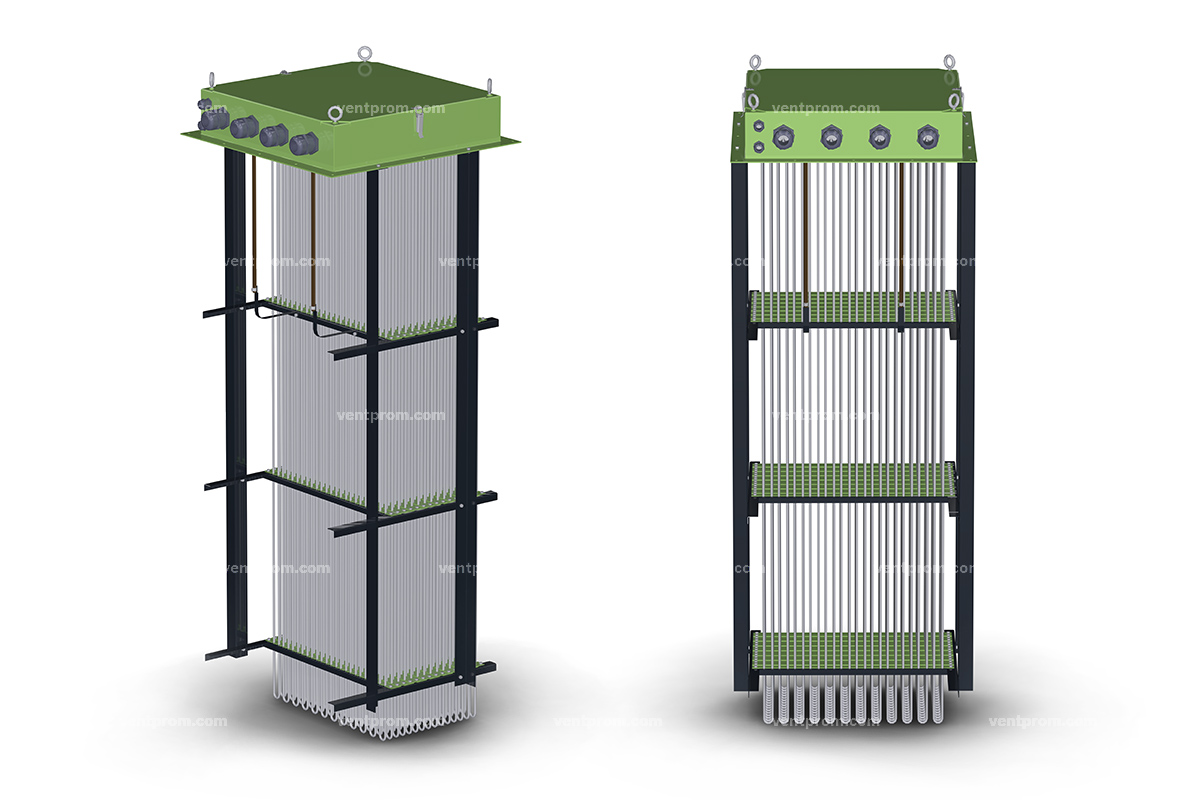

Electriс air heaters structure and description

Heaters housings are made of steel sheet with corrosion-resistant coating ensuring high resistance of metal to corrosion and chemicals.

Heaters are protected by thermostats against overheating and condensation on the electrically conductive parts of the unit.

The structure of the heater ensures its operation in the modes defined by the requirements of the technical specifications.

The structure of the heater ensures its operation in the modes defined by the requirements of the technical specifications.

Scope of supply and MAINTENANCE

The heater scope of supply includes (unless otherwise specified in the application specification):

— heaters of a certain modification

— mounting set

— data sheet and operating manual

— electric circuit diagram

— electrical connection diagram

— specification

— sensors (according to specicfication)

Maintenance of electric air heater should be performed at least once every six months and consists of control of mounting of electric air heater, control of electrical connections, as well as removal of dust and dirt from terminals of electric air heater

— heaters of a certain modification

— mounting set

— data sheet and operating manual

— electric circuit diagram

— electrical connection diagram

— specification

— sensors (according to specicfication)

Maintenance of electric air heater should be performed at least once every six months and consists of control of mounting of electric air heater, control of electrical connections, as well as removal of dust and dirt from terminals of electric air heater

OPERATIONAL CONDITIONS AND CHARACTERISTICS

AUTOMATIC CONTROL SYSTEMS FOR AIR HEATING DEVICES

Systems of automatic air heating control are designed to regulate the temperature of the air flow directed into the mine.

The system consists of the main control cabinet (MCC), local control (LCC) cabinets and power control cabinets (PCC).

The system is built in such a way that a failure of any automation element in the control cabinets will not stop the operation of air heating equipment, since the automatic control system for air heating devices provides redundancy for equipment control channels and also for communication lines between the assemblies of the system.

Fan control systems and automatic control systems for air heating devices can be supplied as a single control complex.

The system consists of the main control cabinet (MCC), local control (LCC) cabinets and power control cabinets (PCC).

The system is built in such a way that a failure of any automation element in the control cabinets will not stop the operation of air heating equipment, since the automatic control system for air heating devices provides redundancy for equipment control channels and also for communication lines between the assemblies of the system.

Fan control systems and automatic control systems for air heating devices can be supplied as a single control complex.

Main control cabinet controls the operation of a set of local control cabinets, it is the central link of temperature control system.

Local control cabinets receive control signals from the main control cabinet and ensure switching on and controlling the operation of the calorifier units.

Power control cabinets contain power equipment for switching power thyristors of heating elements (heaters).

Features of the automatic control systems for air heating devices:

— redundancy of controllers in automatic mode in case of failure of the master (main) PLC;

— duplication of the network communication between the system cabinets via Profi bus DP and Profi net networks;

— the heating is controlled by a PLC via pulse width modulation;

— heating sections are switched by power thyristors;

— the air heating is controlled by PID control ensuring precise compliance with the air temperature setpoint;

— the possibility of setting system parameters from the operator panels installed on the control cabinets doors.

Functions of the automatic control systems for air heating devices

— control of the readiness of the power control cabinets and the system as a whole for operation;

— 660 V voltage control for each transformer;

— ground leakage control;

— PWM control of the air heaters heating power depending on the current air temperature;

— electrical protections of thyristor modules;

— check of serviceability of thyristor modules and their control channels;

— the ability to control and monitor the system via Ethernet;

— Manual and automatic control of local control cabinets operation;

— measurement of amplitude and average current per period and measurement of 660V voltage;

— anti-condensation heating of air heaters;

— creation of databases in the internal archive on the basis of the events, fan operation parameters.

Local control cabinets receive control signals from the main control cabinet and ensure switching on and controlling the operation of the calorifier units.

Power control cabinets contain power equipment for switching power thyristors of heating elements (heaters).

Features of the automatic control systems for air heating devices:

— redundancy of controllers in automatic mode in case of failure of the master (main) PLC;

— duplication of the network communication between the system cabinets via Profi bus DP and Profi net networks;

— the heating is controlled by a PLC via pulse width modulation;

— heating sections are switched by power thyristors;

— the air heating is controlled by PID control ensuring precise compliance with the air temperature setpoint;

— the possibility of setting system parameters from the operator panels installed on the control cabinets doors.

Functions of the automatic control systems for air heating devices

— control of the readiness of the power control cabinets and the system as a whole for operation;

— 660 V voltage control for each transformer;

— ground leakage control;

— PWM control of the air heaters heating power depending on the current air temperature;

— electrical protections of thyristor modules;

— check of serviceability of thyristor modules and their control channels;

— the ability to control and monitor the system via Ethernet;

— Manual and automatic control of local control cabinets operation;

— measurement of amplitude and average current per period and measurement of 660V voltage;

— anti-condensation heating of air heaters;

— creation of databases in the internal archive on the basis of the events, fan operation parameters.

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS