VCD-47 NN 'Sever' is a double-suction centrifugal fan designed for main ventilation of metallurgical and chemical industry mines and coal mines.

VCD-47 NN "Sever" FAN

VCD-47 NN «SEVER» FAN APPLICATION

VCD-47 NN 'Sever' fans have an adjustable electric drive system, and are designed for use in the main ventilation systems of pits, metallurgical and chemical industries, and coal mines. These fans are the largest in terms of ventilation parameters, and designed to supply up to 690 m3/s of air to metro workings within the operating envelope, the pressure developed by the fan can vary from 1000 to 8800 Pa.

—

Can be equipped with automatic control systems

—

Can be equipped with automatic control systems

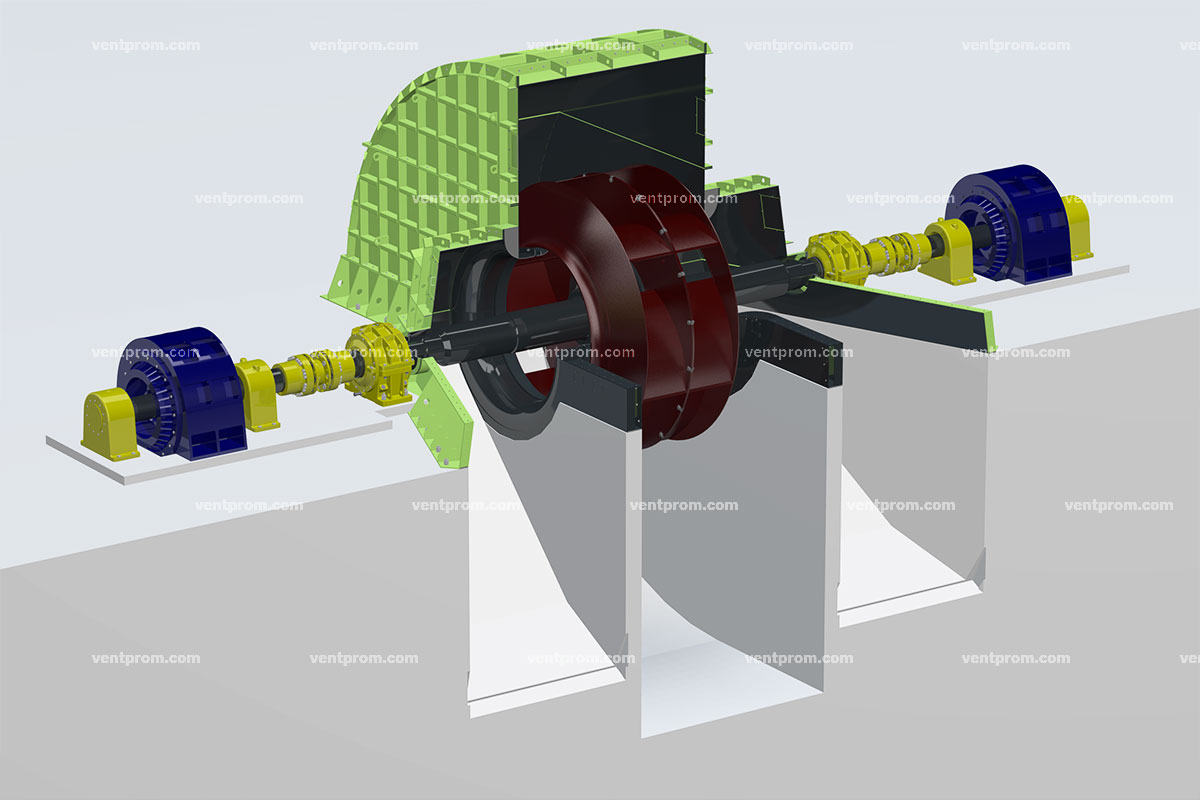

Electric motor

Rotor

Housing

Suction box

Design and special features

VCD-47 NN is a double-suction centrifugal fan. It consists of a rotor with an impeller, a casing, and a power release device. Most part of the fan housing is covered below concrete.

There is also a fan motor control measurement system, and a pressure measurement system. If needed, the fan can be switched on manually according to GOST 11004.

There is also a fan motor control measurement system, and a pressure measurement system. If needed, the fan can be switched on manually according to GOST 11004.

—

The impeller is made of two left and right half rings, each consisting of a main and a cover disc, with profile blades welded between the discs. The impeller blades are filled with polyurethane foam. The half-wheels are fixed on a hub mounted on the main shaft in the middle between the supports. On the outlet ends of the shaft there are gear couplings for connection to the main and acceleration motors.

—

The housing is a single group that combines the spiral diffuser, inlet cones and suction boxes.

The housing has no vertical joints; it consists of two rigid sides and sections of spiral shell covering the middle part of the housing at the periphery. For ease of transportation, the sidewalls have removable top shields, which are welded to the sidewalls on the connector flanges after installation is completed.

A horizontal joint separates the upper part of the housing from the rigid frame belt installed directly on the concrete and consisting of side beams, a crossbar and a tongue.

All parts of the housing are metal structures.

The impeller is made of two left and right half rings, each consisting of a main and a cover disc, with profile blades welded between the discs. The impeller blades are filled with polyurethane foam. The half-wheels are fixed on a hub mounted on the main shaft in the middle between the supports. On the outlet ends of the shaft there are gear couplings for connection to the main and acceleration motors.

—

The housing is a single group that combines the spiral diffuser, inlet cones and suction boxes.

The housing has no vertical joints; it consists of two rigid sides and sections of spiral shell covering the middle part of the housing at the periphery. For ease of transportation, the sidewalls have removable top shields, which are welded to the sidewalls on the connector flanges after installation is completed.

A horizontal joint separates the upper part of the housing from the rigid frame belt installed directly on the concrete and consisting of side beams, a crossbar and a tongue.

All parts of the housing are metal structures.

TECHNICAL SPECIFICATIONS

AERODYNAMIC CHARACTERISTICS

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS