Mine ventilation control systems manufactured by AO AMZ Ventprom fully comply with the safety requirements for such systems, providing continuous control of the fans` operation

Automation of main ventilation system

FOR MINES

Purpose

Mine ventilation control systems manufactured by AO AMZ Ventprom fully comply with the safety requirements for such systems, providing continuous control of the fans` operation. A built-in algorithm for automatic switching from the main fan to a standby fan in case of emergency ensures an uninterrupted supply of air into the shaft, which is necessary for most similar facilities.

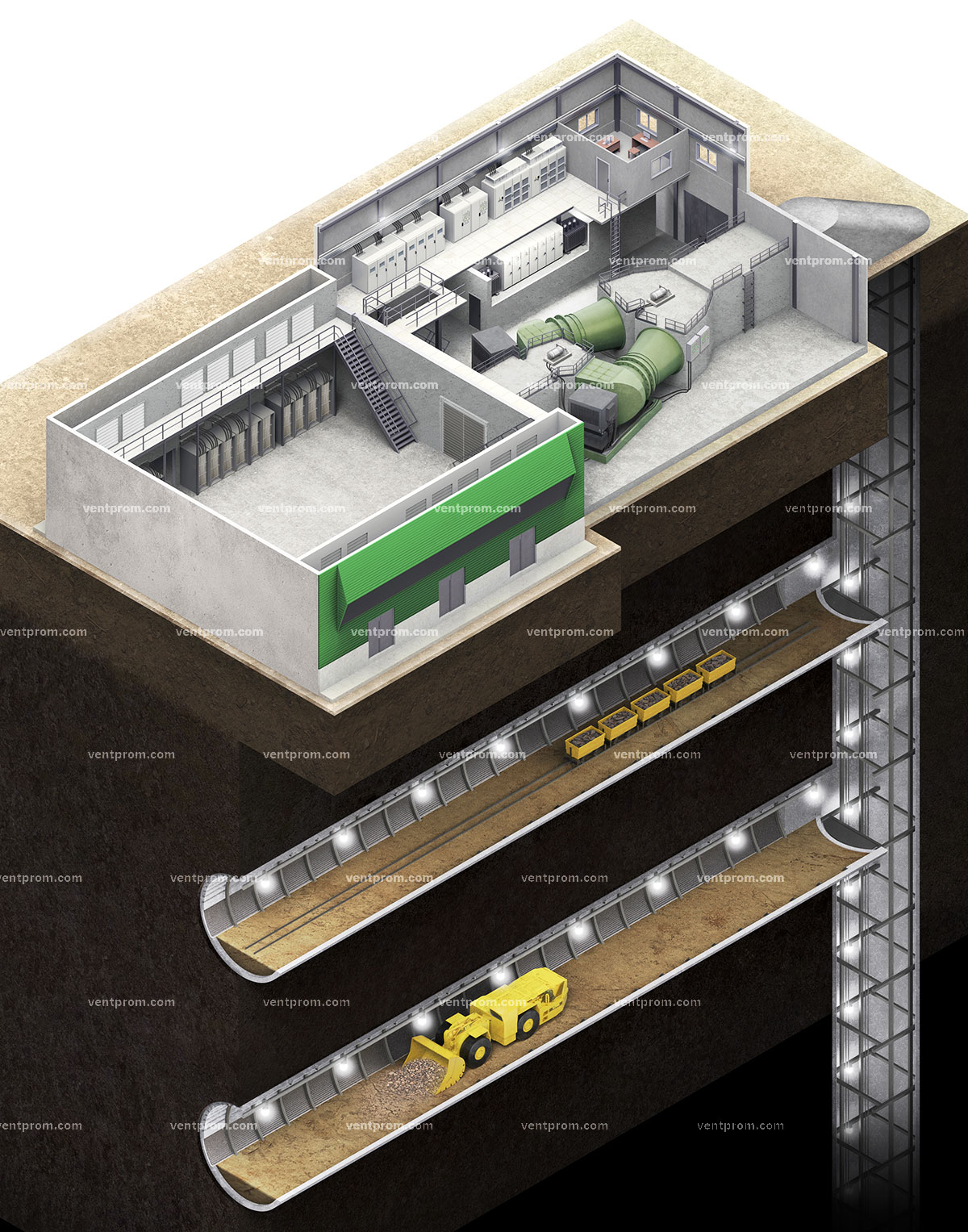

ACS for calorifiers

ACS for fans

High-voltage frequency converters

Operator room

Machine room (fan room)

Control panels

AVM ventilation unit

Air intake to the ventilation unit

Calorifier unit room

Air gates

Air intake to the calorifier unit room

6kV cells and transformer

Supply of air from the fan into the ventilation shaft

Ventilation shaft

Horizontal workings

MINE VENTILATION ARRANGEMENT

Powerful ventilation units provide an air supply for ventilation of mine workings. As a rule, they are located aboveground and supply air to mine workings through a ventilation shaft.

The temperature of the air fed into a mine should be at least +2 degrees, so in the cold season, the air is heated with the help of air heaters located at the entrance to the air duct.

In addition to ventilation units, control systems, high-voltage equipment, control panels, and operator's computer (APC) are located in a machine room.

All this equipment operates in a single complex controlled by the ACS systems in automatic mode.

The temperature of the air fed into a mine should be at least +2 degrees, so in the cold season, the air is heated with the help of air heaters located at the entrance to the air duct.

In addition to ventilation units, control systems, high-voltage equipment, control panels, and operator's computer (APC) are located in a machine room.

All this equipment operates in a single complex controlled by the ACS systems in automatic mode.

01

Air gates. The air supplied to a mine is heated by passing through the calorifier units. The gates are closed at this time. The air gates are open when the fan is in reversed mode or during the warm season when air heating is not required.

02

The air is supplied to mine workings through a ventilation shaft to meet the necessary standards for the concentration of explosive substances and renew the air mixture in the workings.

03

Operator room. The ventilation units are controlled and monitored from here. All data from the ACS are transferred to an automated operator workstation (computer – APC), where they are archived, and the ventilation unit's current parameters are displayed. Also, data on the ventilation unit operation is transmitted to a common control center of a mine

Air gates. The air supplied to a mine is heated by passing through the calorifier units. The gates are closed at this time. The air gates are open when the fan is in reversed mode or during the warm season when air heating is not required.

02

The air is supplied to mine workings through a ventilation shaft to meet the necessary standards for the concentration of explosive substances and renew the air mixture in the workings.

03

Operator room. The ventilation units are controlled and monitored from here. All data from the ACS are transferred to an automated operator workstation (computer – APC), where they are archived, and the ventilation unit's current parameters are displayed. Also, data on the ventilation unit operation is transmitted to a common control center of a mine

System features

High reliability and failure-free operation of a control system are achieved due to:

– full redundancy of the ACS systems, providing continuous air supply to a mine;

– autonomous control of all system parameters (in case of critical failure of the operating unit, automatic switching to a standby mode is performed);

– function of forecasting of emergencies (the system monitors the change of temperature and vibration of the equipment within a specified period, apart from the emergency settings);

– creation of an archive database with all control commands, parameters, and diagnostic signals of the system;

– realization of the uninterrupted supervisory control and management system.

– full redundancy of the ACS systems, providing continuous air supply to a mine;

– autonomous control of all system parameters (in case of critical failure of the operating unit, automatic switching to a standby mode is performed);

– function of forecasting of emergencies (the system monitors the change of temperature and vibration of the equipment within a specified period, apart from the emergency settings);

– creation of an archive database with all control commands, parameters, and diagnostic signals of the system;

– realization of the uninterrupted supervisory control and management system.

Technical specifications and system functions

Control systems of the main ventilation of mines are developed according to the customer's design and technical requirements.

A control system can be supplied with a set of high-voltage equipment (cells, transformers, high-voltage contactors, frequency converters, or soft starters) and all the necessary sensors to monitor the parameters of ventilation units.

A control system implements a fan and auxiliary equipment control algorithm. In case of a short-term power failure, it automatically switches on again or provides redundancy of the high-voltage bus sections.

Control systems are designed to control both low-voltage and high-voltage electrical equipment of an automated complex.

High-power uninterruptible power supply units installed in a control system enable supervisory control and monitoring of a system even in case of power failure of control cabinets.

A control system can be supplied with a set of high-voltage equipment (cells, transformers, high-voltage contactors, frequency converters, or soft starters) and all the necessary sensors to monitor the parameters of ventilation units.

A control system implements a fan and auxiliary equipment control algorithm. In case of a short-term power failure, it automatically switches on again or provides redundancy of the high-voltage bus sections.

Control systems are designed to control both low-voltage and high-voltage electrical equipment of an automated complex.

High-power uninterruptible power supply units installed in a control system enable supervisory control and monitoring of a system even in case of power failure of control cabinets.

Control system functions

– control of the fans` readiness for a start-up;

– start-up and frequency regulation of the fan rotation speed;

– continuous control of all operating parameters of the fans;

– automatic switching from the operating fan to the standby fan in case of emergency;

– manual and automatic control of all actuating mechanisms;

– possibility of automatic switching of the reserve power input in case of failure of the operating input;

– self-diagnostics of the system failures;

– automatic switching of the reserve low-voltage input (built-in 380V ATS);

– electric protection of motors of main and auxiliary drives;

– control of all modes of fan operation from the computer;

– data transmission on the fan operation via the local information network;

– collection, processing, and storage of the ventilation unit operation data

– creating of screen forms and charts of the fan operation parameters on the operator's computer

– start-up and frequency regulation of the fan rotation speed;

– continuous control of all operating parameters of the fans;

– automatic switching from the operating fan to the standby fan in case of emergency;

– manual and automatic control of all actuating mechanisms;

– possibility of automatic switching of the reserve power input in case of failure of the operating input;

– self-diagnostics of the system failures;

– automatic switching of the reserve low-voltage input (built-in 380V ATS);

– electric protection of motors of main and auxiliary drives;

– control of all modes of fan operation from the computer;

– data transmission on the fan operation via the local information network;

– collection, processing, and storage of the ventilation unit operation data

– creating of screen forms and charts of the fan operation parameters on the operator's computer

OTHER PRODUCTS