Provision of the required climatic conditions in stations and tunnels, including emergencies. These functions are provided by underground ventilation equipment, which is monitored and controlled by an automated system.

UNDERGROUND RAILWAYS LIFE SUPPORT MANAGEMENT

Purpose

The required climatic conditions in stations and tunnels, including emergencies, are provided by underground ventilation equipment monitored and controlled by an automated system.

The underground railway ventilation control system is an automated complex that provides power supply, controls electric drives` operation and technological parameters of an air handling unit operation, and all the necessary operating modes and information transfer via local networks to the metro control center.

The underground railway ventilation control system is an automated complex that provides power supply, controls electric drives` operation and technological parameters of an air handling unit operation, and all the necessary operating modes and information transfer via local networks to the metro control center.

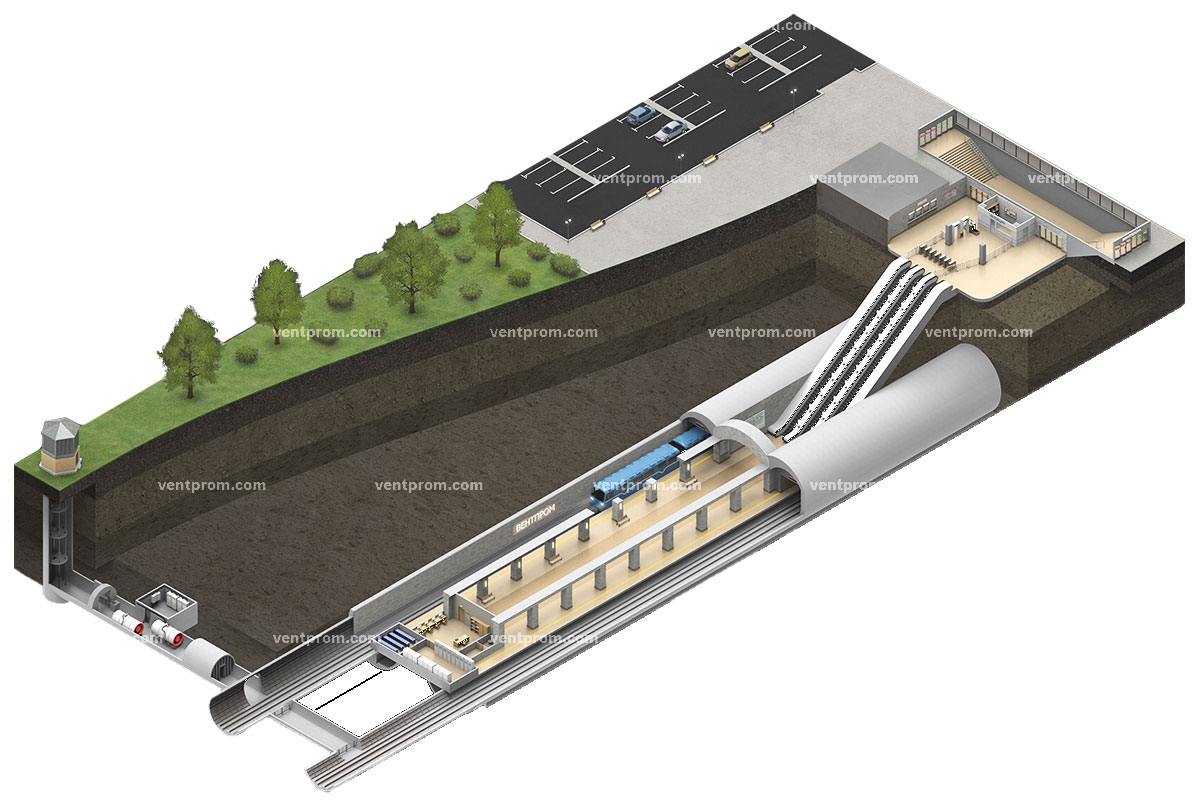

Ventilation vault

Ventilation shaft

Electrical equipment room

VOM ventilation units

Underground tunnels

Control center

Underground station

Station entrance

Trains create a so-called "piston effect" as they move through the tunnel, forcing airflow through the underground tunnel. But this amount of air is not enough to provide an optimal microclimate in underground stations and tunnels.

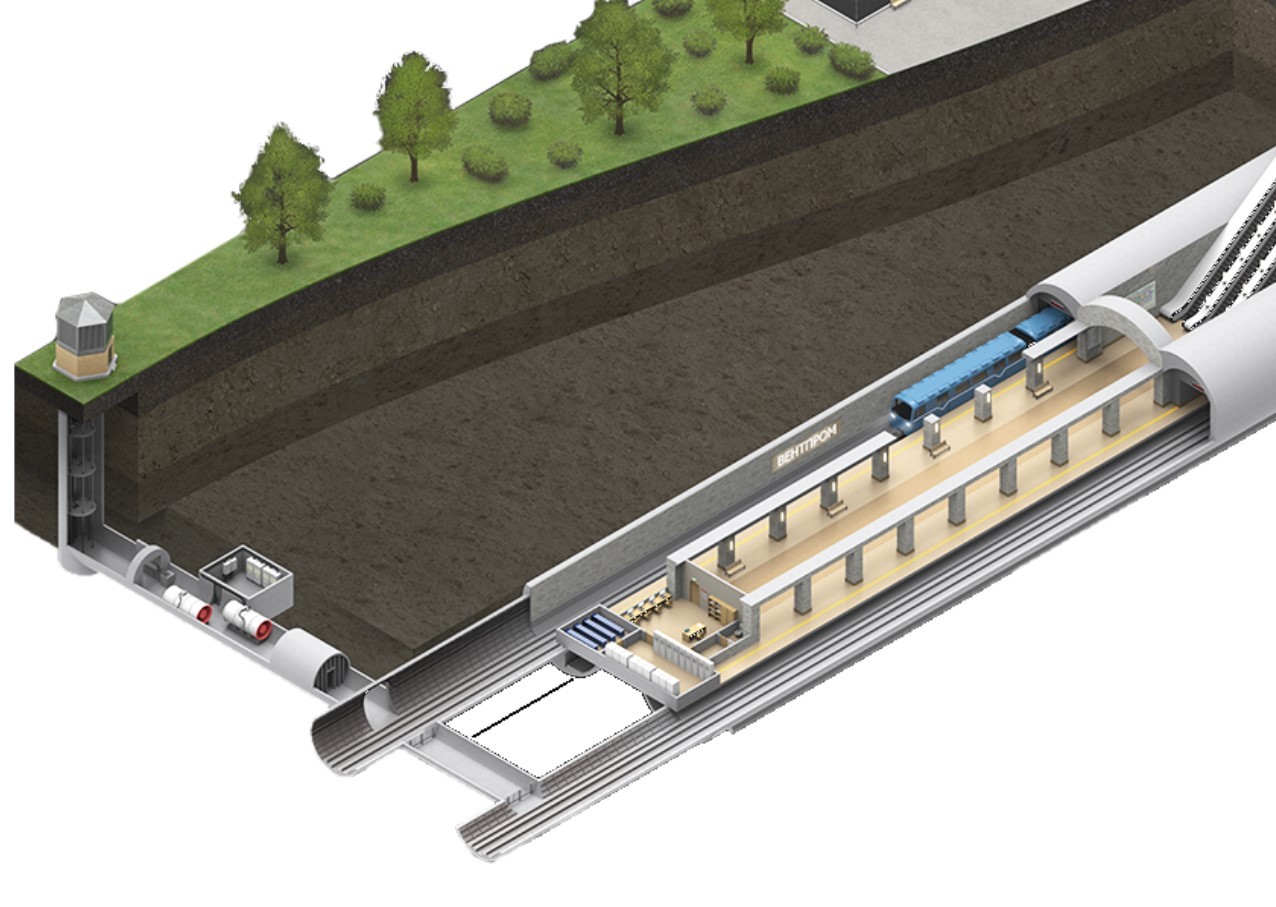

Ventilation vault

Ventilation shaft

Electrical equipment room

VOM ventilation units

Underground tunnels

Control center

Underground station

Station entrance

UNDERGROUND RAILWAYS VENTILATION ARRANGEMENT

Station ventilation (in the station space), station-to-station block (i.e., between stations), and dead-end ventilation shafts (for ventilation of reverse and dead-end tunnels) are created to provide ventilation in underground tunnels. All of these facilities operate in the common automated ventilation system of an underground.

In summer, the air is supplied through station shafts and is exhausted from underground station-to-station block shafts. In winter, on the contrary, the air is supplied through station-to-station blocks and is removed through station ventilation shafts. In such operation mode in winter, the air warms up as it passes through the tunnel toward the station.

In summer, the air is supplied through station shafts and is exhausted from underground station-to-station block shafts. In winter, on the contrary, the air is supplied through station-to-station blocks and is removed through station ventilation shafts. In such operation mode in winter, the air warms up as it passes through the tunnel toward the station.

01

A ventilation vault through which air is taken in/out for ventilation of underground tunnels. Also, ventilation vaults provide access to ventilation units, ACS systems, and underground tunnel for technical staff to perform maintenance and regulatory works.

02

VOM ventilation units. As a rule, they are duplicated to ensure uninterrupted ventilation of tunnels.

03

Electrical equipment room. ACS systems, ATS cabinets, and other electrical equipment automation cabinets of a tunnel are located here.

04

Control center. It is designed for visualization and remote control of electrical equipment of the monitored underground zone. Remote start and ACS systems` control can be performed from a control center.

05

Trains create a so-called "piston effect" as they move through the tunnel, forcing airflow through the underground tunnel. But this amount of air is not enough to provide an optimal microclimate in underground stations and tunnels.

A ventilation vault through which air is taken in/out for ventilation of underground tunnels. Also, ventilation vaults provide access to ventilation units, ACS systems, and underground tunnel for technical staff to perform maintenance and regulatory works.

02

VOM ventilation units. As a rule, they are duplicated to ensure uninterrupted ventilation of tunnels.

03

Electrical equipment room. ACS systems, ATS cabinets, and other electrical equipment automation cabinets of a tunnel are located here.

04

Control center. It is designed for visualization and remote control of electrical equipment of the monitored underground zone. Remote start and ACS systems` control can be performed from a control center.

05

Trains create a so-called "piston effect" as they move through the tunnel, forcing airflow through the underground tunnel. But this amount of air is not enough to provide an optimal microclimate in underground stations and tunnels.

FUNCTIONAL CAPABILITIES OF UNDERGROUND FANS` CONTROL SYSTEM

— continuous control of the system equipment parameters (fans vibration, bearings temperature, motor current, air pressure/flow/temperature control);

– option for fans operation by the operator-defined histogram of rotation speed (in this case the system automatically regulates the amount of air supplied to the tunnel during the preset time);

– realization of the supervisory control of the system, monitoring and archiving of the data by means of Modbus RTU or Modbus TCP protocols from the operator's computer (APC);

– possibility of integration in the system of redundant control equipment, based on using two PLCs for the system control (one PLC is the main, the other is standby);

– usage of a minimum number of electromagnetic relays in control cabinets to increase its reliability.

— continuous control of the system equipment parameters (fans vibration, bearings temperature, motor current, air pressure/flow/temperature control);

– option for fans operation by the operator-defined histogram of rotation speed (in this case the system automatically regulates the amount of air supplied to the tunnel during the preset time);

– realization of the supervisory control of the system, monitoring and archiving of the data by means of Modbus RTU or Modbus TCP protocols from the operator's computer (APC);

– possibility of integration in the system of redundant control equipment, based on using two PLCs for the system control (one PLC is the main, the other is standby);

– usage of a minimum number of electromagnetic relays in control cabinets to increase its reliability.

FUNCTIONS EXECUTED BY THE CONTROL SYSTEM

– control of readiness of a fan system for operation; – control of insulation resistance of main drive motors;

– control of current parameters of fan operation (motor temperature, vibration level);

– fan operation according to the preset rotation frequency variation schedule (frequency histogram);

– frequency control of the fan rotation speed;

– motor start in local and remote modes without participation of frequency converter and logic controller in case of their failure;

– functional check of drives;

– programmable blockings of the fan start;

– programmable protection of the main drive motor;

– heating of the main drive motor in standby mode;

– creating databases of events, fan operation parameters in internal storage;

– possibility of control and monitoring of the system via Modbus TCP/RTU network;

– maintaining working temperatures inside a control cabinet;

– possibility of control of the system from remote and local control panel.

– control of readiness of a fan system for operation; – control of insulation resistance of main drive motors;

– control of current parameters of fan operation (motor temperature, vibration level);

– fan operation according to the preset rotation frequency variation schedule (frequency histogram);

– frequency control of the fan rotation speed;

– motor start in local and remote modes without participation of frequency converter and logic controller in case of their failure;

– functional check of drives;

– programmable blockings of the fan start;

– programmable protection of the main drive motor;

– heating of the main drive motor in standby mode;

– creating databases of events, fan operation parameters in internal storage;

– possibility of control and monitoring of the system via Modbus TCP/RTU network;

– maintaining working temperatures inside a control cabinet;

– possibility of control of the system from remote and local control panel.

OTHER PRODUCTS