Reversible axial single-stage fans of the VO-RAR series are designed for for wide industrial applications in reversible ventilation systems, including the ventilation of closed and operating mines, pits, subways, and tunnels with an air supply range of 5-1100 m3/s and static pressure of 100-8500 Pa.

VO-AR FAN

VО-AR fan application

Reversible axial single-stage fans of the VO-AR series are designed for for wide industrial applications in reversible ventilation systems, including the ventilation of closed and operating mines, pits, subways, and tunnels with an air supply range of 5-1100 m3/s and static pressure of 100-8500 Pa.

Standard size range VO-12AR, VO-14AR, VO-16AR, VO-18AR, VO-21AR, VO-22AR, VO-24AR, VO-26AR, VO-28AR, VO-30AR, VO-32AR, VO-34AR, VO-36AR, VO-38AR, VO-40AR, VO-42AR, VO-45AR, VO-50AR (axial fan - impeller diameter in dm - reverse type)

Standard size range VO-12AR, VO-14AR, VO-16AR, VO-18AR, VO-21AR, VO-22AR, VO-24AR, VO-26AR, VO-28AR, VO-30AR, VO-32AR, VO-34AR, VO-36AR, VO-38AR, VO-40AR, VO-42AR, VO-45AR, VO-50AR (axial fan - impeller diameter in dm - reverse type)

Electric motor

Frame

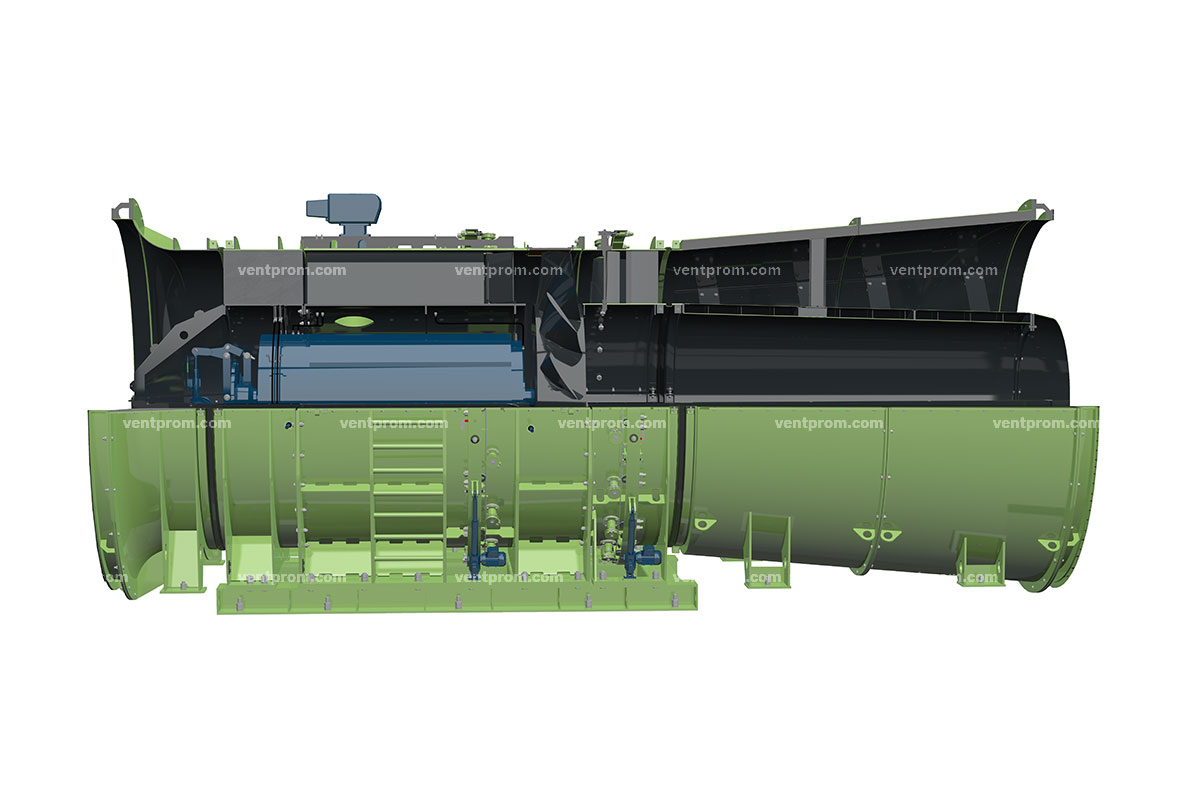

VO-AR design

The fans are based on modifications of a high speed special reversible aerodynamic configuration, which ensures the full efficiency of the fan with inlet box and diffuser at the level of 80%

—

U and T climatic categories of the fans, placement category 3 according to GOST 15150, climatic categories of the fans electrical equipment are specified in its manuals.

—

The fans are manufactured either with

remote (VO-A) or built-in

(VO-AV) electric motors

—

Can be operated in both suction and discharge ventilation systems.

—

Suitable for other systems that supply air with the specified parameters.

—

U and T climatic categories of the fans, placement category 3 according to GOST 15150, climatic categories of the fans electrical equipment are specified in its manuals.

—

The fans are manufactured either with

remote (VO-A) or built-in

(VO-AV) electric motors

—

Can be operated in both suction and discharge ventilation systems.

—

Suitable for other systems that supply air with the specified parameters.

Fan switching to reverse mode is made by reversing the rotor rotation direction (with appropriate reversal of flaps in case of guide vane equipped models) with flow ratio 80% and more at rated power mode when forward and reverse flow

Fans operation mode regulation is performed by changing the impeller blades setting angle when the fan is stopped (basic version), or on-the-go by turning the guide vane flaps with electromechanical actuator (combination of these two methods ensures the highest regulation efficiency)

The use of adjustable guide vanes improves reversibility and increases the maximum fan pressure by 15-20% compared to the basic version without reducing the achieved efficiency level

The rotor group and impeller blade system of each fan size are optimized by finite-element, strength and frequency analysis methods with careful tuning out of resonance modes

Mounting of the fan and motor on a common frame without an intermediate shaft increases the operational reliability of the unit

Modifications with special high-performance anti-stall devices guarantee stable aerodynamic performance of the fans in case of ventilation systems with variable characteristics

The modern methods of aeroacoustic design of blade systems and elements of the fans flow channel ensure a minimum level of noise generation directly in the source of formation.

Fans operation mode regulation is performed by changing the impeller blades setting angle when the fan is stopped (basic version), or on-the-go by turning the guide vane flaps with electromechanical actuator (combination of these two methods ensures the highest regulation efficiency)

The use of adjustable guide vanes improves reversibility and increases the maximum fan pressure by 15-20% compared to the basic version without reducing the achieved efficiency level

The rotor group and impeller blade system of each fan size are optimized by finite-element, strength and frequency analysis methods with careful tuning out of resonance modes

Mounting of the fan and motor on a common frame without an intermediate shaft increases the operational reliability of the unit

Modifications with special high-performance anti-stall devices guarantee stable aerodynamic performance of the fans in case of ventilation systems with variable characteristics

The modern methods of aeroacoustic design of blade systems and elements of the fans flow channel ensure a minimum level of noise generation directly in the source of formation.

Design versions of the VO-AR fan series

VO-A

emote electric motor

VO-AV

Built-in electric motor

AERODYNAMIC CHARACTERISTICS

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS