VC-15 centrifugal fan is designed for main and auxiliary ventilation of coal mines, pits, as well as for shaft ventilation during sinking.

VC-15 FAN

VC-15 FAN APPLICATION

VC-15 centrifugal fan is designed for main and auxiliary ventilation of coal mines, pits, as well as for shaft ventilation during sinking.

VC-15 fan is installed on the surface of mines and pits in specially equipped buildings with the indoor temperature not lower than +1 оC, at the ventilated air temperature from 228 to 323 K, dust content up to 150 mg/m and relative humidity up to 98%, at the height above sea level up to 1000 m.

The fan can be used for both suction and discharge ventilation systems. Two reversing device versions are available.

VC-15 fan is installed on the surface of mines and pits in specially equipped buildings with the indoor temperature not lower than +1 оC, at the ventilated air temperature from 228 to 323 K, dust content up to 150 mg/m and relative humidity up to 98%, at the height above sea level up to 1000 m.

The fan can be used for both suction and discharge ventilation systems. Two reversing device versions are available.

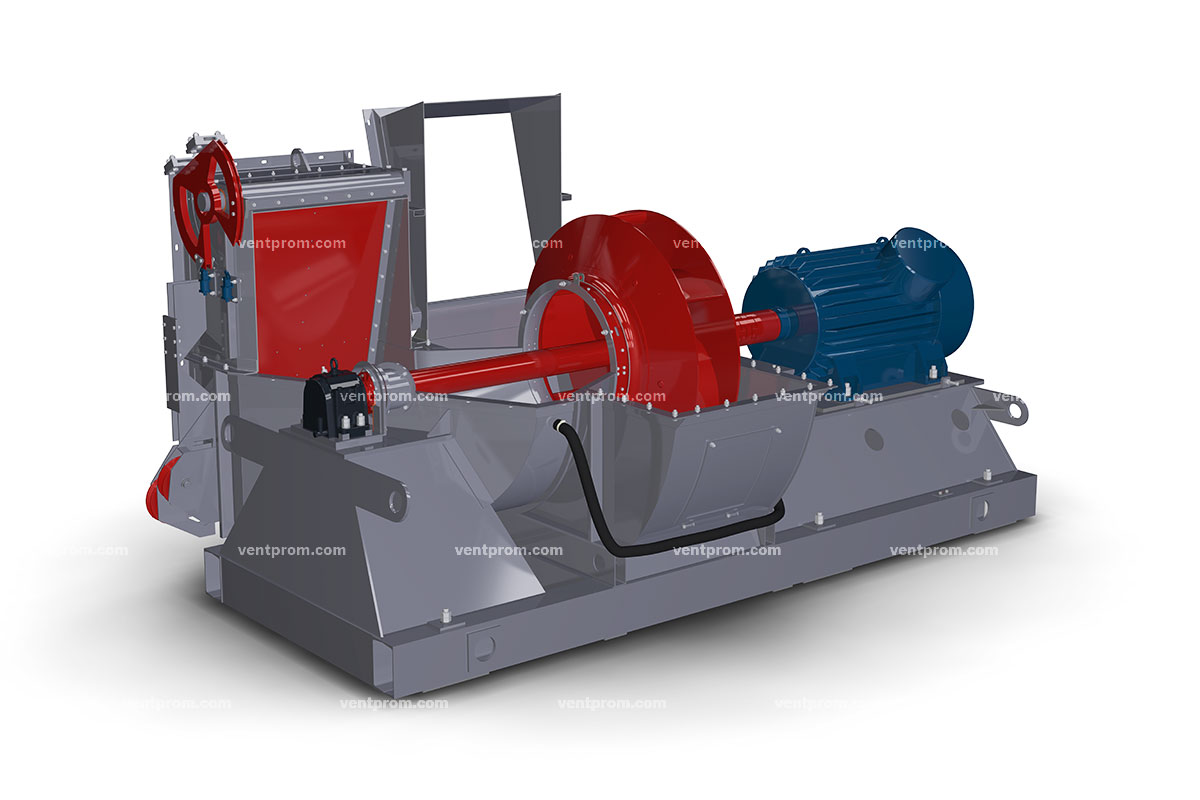

Electric motor

Working wheel

Frame

VC-15 fan design

VC-15 fan is fully mounted on a frame, which allows you to quickly install it at the operating site, dismantle it and move to another place.

It consists of a frame, a rotor with support bearings, a spiral housing, a vortex inlet guide vane with an actuator and an electric motor connected to the rotor shaft by a coupling.

It consists of a frame, a rotor with support bearings, a spiral housing, a vortex inlet guide vane with an actuator and an electric motor connected to the rotor shaft by a coupling.

—

The fan frame is all-welded, rolled steel structure with two pedestals for mounting rotor bearings and electric motors. The frame is installed on the foundation with anchor bolts.

—

The rotor consists of a shaft with an impeller mounted on a key, and profiled volumetric blades. The shaft rotates in two spherical roller bearings, and their temperature is monitored by thermosensors. The bearing grease is thick and fed via grease nipples.

—

The torque from the motor to the rotor is transmitted through a coupling. The rotor is equipped with a ratchet device for reversing the air jet when the fan is stopped.

—

The spiral housing is a welded metal structure, reinforced by ribs, and can be split horizontally into two halves. The suction cone and inlet box are welded to the housing.

—

The vortex guide vane is a welded steel structure reinforced with ribs. The vortex guide vane is made as a box, with a guide vane mounted on the suction side, which allows to regulate the air flow into the impeller through the box and the suction cone. The winch rope turns the lever attached to the duct door axle, changing its angle inside the box.

—

The air jet reversing (suction and discharge) kit consists of of all-welded reversing boxes equipped with crossover duct doors.

—

The electric motor is bolted to the frame and connected to the rotor shaft by a coupling.

The fan frame is all-welded, rolled steel structure with two pedestals for mounting rotor bearings and electric motors. The frame is installed on the foundation with anchor bolts.

—

The rotor consists of a shaft with an impeller mounted on a key, and profiled volumetric blades. The shaft rotates in two spherical roller bearings, and their temperature is monitored by thermosensors. The bearing grease is thick and fed via grease nipples.

—

The torque from the motor to the rotor is transmitted through a coupling. The rotor is equipped with a ratchet device for reversing the air jet when the fan is stopped.

—

The spiral housing is a welded metal structure, reinforced by ribs, and can be split horizontally into two halves. The suction cone and inlet box are welded to the housing.

—

The vortex guide vane is a welded steel structure reinforced with ribs. The vortex guide vane is made as a box, with a guide vane mounted on the suction side, which allows to regulate the air flow into the impeller through the box and the suction cone. The winch rope turns the lever attached to the duct door axle, changing its angle inside the box.

—

The air jet reversing (suction and discharge) kit consists of of all-welded reversing boxes equipped with crossover duct doors.

—

The electric motor is bolted to the frame and connected to the rotor shaft by a coupling.

TECHNICAL SPECIFICATIONS

AERODYNAMIC CHARACTERISTICS

WE'LL MANUFACTURE A PRODUCT WITH CHARACTERISTICS YOU NEED

Each product we manufacture at AO AMZ VENTPROM is adapted to customer needs and operating characteristics

OTHER PRODUCTS